احصل على

2016年2月24日 There are three main steps in designing a good crushing plant: process

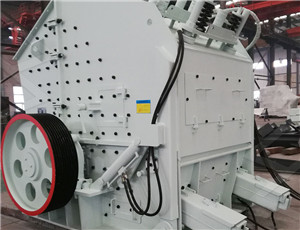

Cement Manufacturing Equipment Cement Crusher Crusher is a kind of machinery that is widely used in the cement production industry It is mainly used in the material preparation process to crush the raw materials into proper size particles AGICO offers 4 types of

2023年9月5日 Fabo What is a Crusher Plant and What is it Used for? Crushing Plant is

Raw materials used for crushing unit Coal, Stone, Granite, limestone, Basalt, River stone, andesite calcite, abrasive rocks, glass, and ferrous

1 天前 Industrial crushers reduce large rocks, ore, or waste materials to smaller sizes

Basalt is a very hard type of rock, therefore, this crusher plant was outfitted by our specialist with a jaw crusher and a compound cone crusher Raw materials used: basalt; Production capacity: 250t/h; Finished product

2023年8月20日 Crushers are used to break up large pieces of rock and bulk materials

A crushing plant setup is a series of machines that are designed to take large pieces of

2020年4月20日 There’s a wide range of equipment that can be used for crushing materials Different crushers are used depending on the type of material you’re trying to crush Some crushing equipment is better for

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt In most crushing installations a jaw crusher takes care of primary crushing Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher

2016年4月7日 In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used If material is easily crushed and not excessively abrasive, an

Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

2016年2月24日 can all affect crusher plant design Construction costs are generally much greater at high altitudes, in cold climates and at remote sites To improve the economics of such locations, modular and preassembled structures and plant facilities are used prior to transportation to site Local labor costs often dictate what material

2018年12月11日 construction materials include; other construction materials, dimension stones, roofing stones, embankment materials etc the purposes of this study are to explore the production and uses of crushed rock aggregates Crushedrock aggregate is the sized or crushed and sized rock material used in rigid and flexible highway pavements

2022年10月12日 A ball milling crusher uses a powder grinding mill used to grind ores and other materials mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls or ceramic are used in the

2021年2月5日 Crushers of different designs are used to produce crushed stone: roller, cone, cheek crushers [36] Roll plants crush stone as a result of its crushing Their structure is based on two horizontal shafts arranged in parallel They rotate in opposite directions The feed material passes between the shafts and is crushed into several parts

2023年2月3日 Published Feb 3, 2023 + Follow In a typical crushing plant, the following machines are commonly used: Jaw Crusher: A jaw crusher is used for primary crushing It uses compressive force to crush

76 Problems 71 A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μm

2019年7月20日 Aggregate crushing plants are important equipment for aggregate processing Aggregate commonly is classified into two categories: fine aggregate and coarse aggregate Fine aggregate is the materials that could pass the No4 sieve, and most could be retained on a No 200 sieve Coarse aggregate is a relatively big materials that will get

2022年5月14日 Impact crushers are most commonly used in stone quarrying industry for making finegrained stones used in road and building materials The impact crusher as shown in Fig 6 feed the material into the crushing chamber where a rotating disc containing hammer is working The rotating action of the hammer apply heavy blow over the feed

2018年12月26日 Efficiency of a multiple stage crushing plant can be maximized by operating a primary crusher at a setting which produces a satisfactory feed size for the secondary crusher and Removing all sizes smaller than output top size from the crusher input material Side Liners / Cheek Plates Wear plates used to protect the crusher frame

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applications

2020年5月6日 Gyratory crusher Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out

2023年3月1日 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials The crushed material is then used as an input into the

2022年1月1日 Fig 5 shows the mean elongation of the four coarse aggregate fractions for JC and JJ crushers The test results showed that the particles obtained from JC crusher indicated lesser elongation in comparison with JJ crusher For all the size ranges, American Society for Testing and Materials (ASTM) and Indian Standards (IS) specifies a minimum

2022年10月24日 This research was conducted to examine the potential of basaltic crusher dust as a partial replacement for Portland Pozzolana cement in hollow concrete block (HCB) production Quarry dust is one of the waste materials abundantly available and pozzolanic material in the quarry industry In doing so, physical tests of cement pastes and hollow

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularization

2021年8月15日 The approach provides interesting insights into the effects of liner wear and mean time to failure on the capacity, quality and financial profit of the crushing plant Bhadani et al (2018) used the crusher model reported in Asbjörnsson et al (2012) to propose a multidisciplinary optimization platform for crushing plants An example